PROCESS ANALYSIS & CONTROL

"Optimizing efficiency and quality through precise process analysis and advanced process control"

By analyzing each step of the production process, companies can identify areas for improvement and implement strategies to optimize performance. Lumatics helps you to use ressources efficiently, minimize costs, and meet quality standards by implementing modern algorithms like model predictive control (MPC).

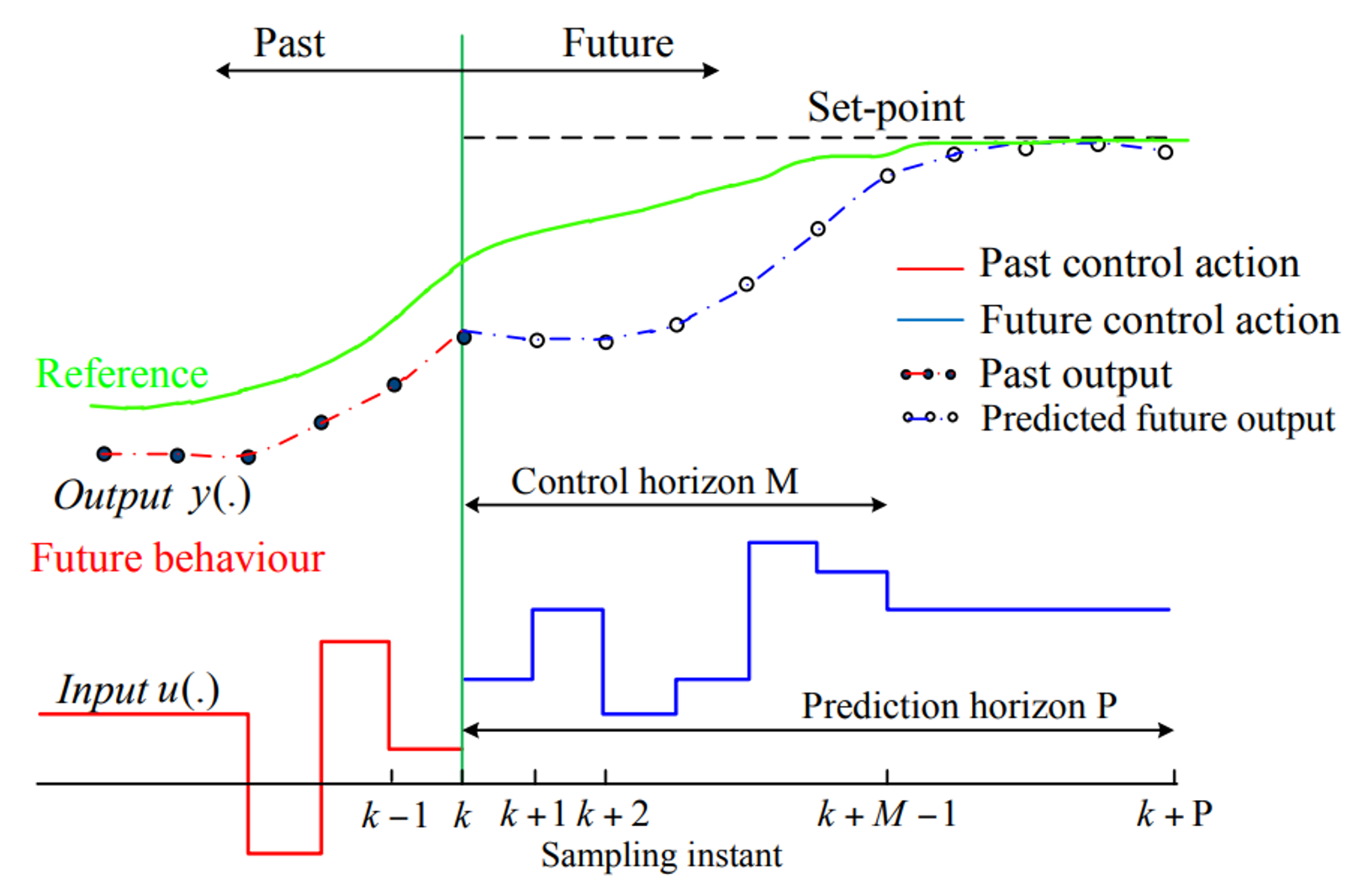

It is a sophisticated, optimal control strategy that uses mathematical models to predict future process behavior and optimize control actions. By continuously updating these models based on real-time data, MPC can effectively regulate key process variables such as material mix, product consistency and mill performance to achieve desired outcoms. By taking into account various constraints and objectives, MPC can dynamically adjust control setpoints to maximize performance while ensuring safe and reliable operation. Overall, the implementation of MPC in cement process control can lead to significant cost savings and environmental benefits.

SENSORS & DATA INSIGHTS

"Sensors empower data-driven decisions for peak performance."

All information comes from sensors. Without process and data insights no analysis and optimisation can take place. Lumatics provides you with a wide variety of sensors to collect required data. This lies the foundation for process analysis, control and optimization.

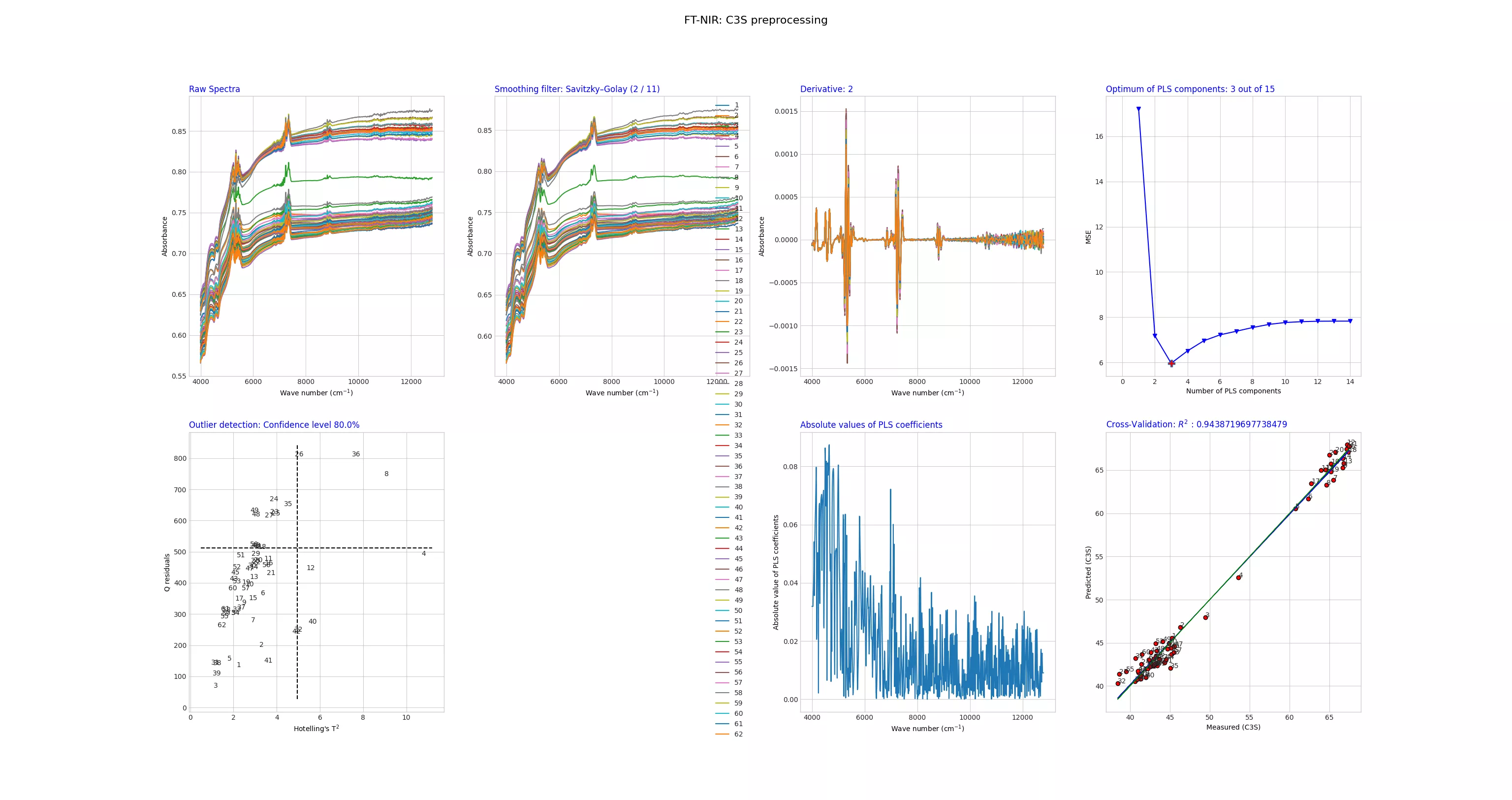

Lumatics broad experience in the field of cement analysis by infrared measurements simplifies integration of spectrometers that allow to go new ways in substance detection and quantification. Patent-pending at-line technology guarantees easy integration into your process.

Artificial Intelligence based analysis methods returns cutting edge insights to our customers.

CONSULTING & YOUR PARTNER

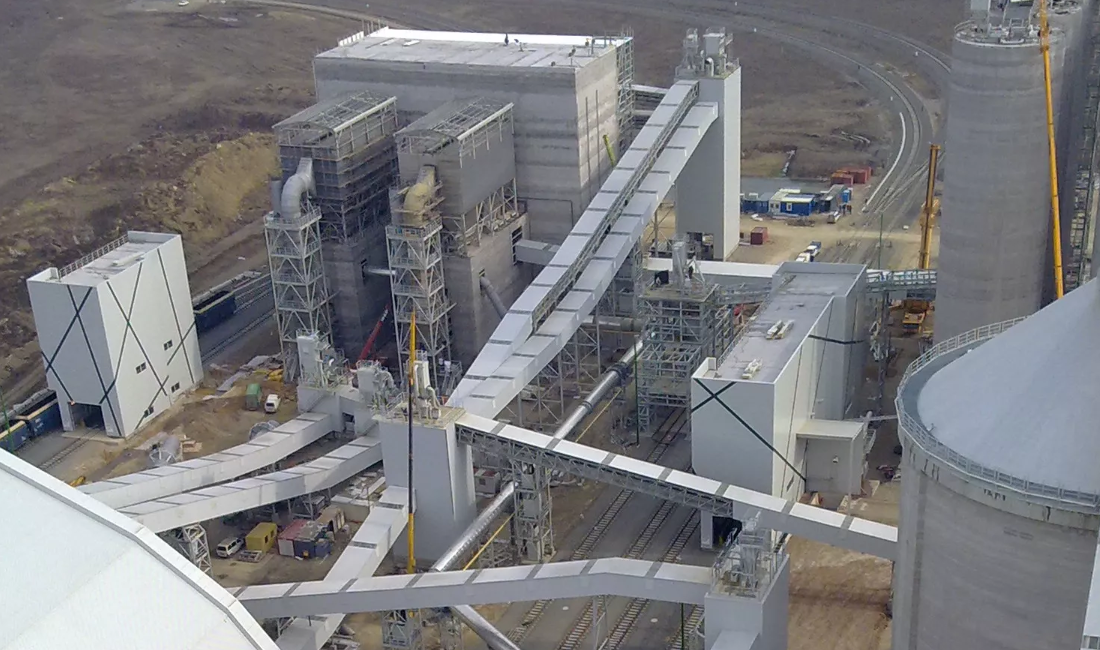

"Focusing on industrial processes in the cement industry is crucial to improving efficiency, productivity and sustainability in production".

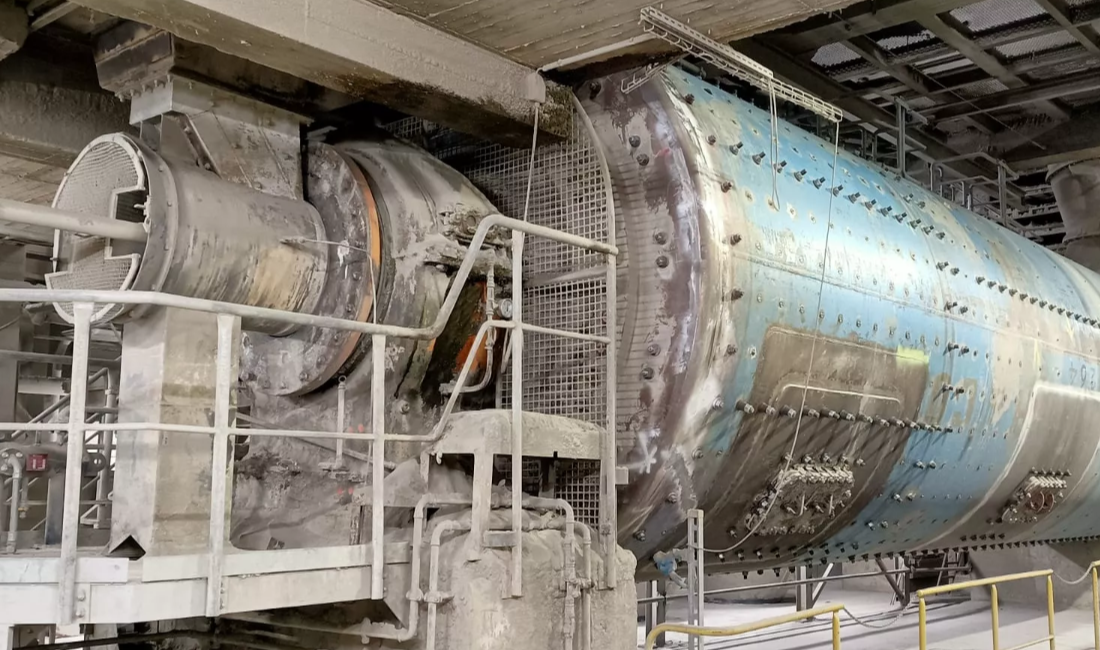

By optimizing processes, resources can be saved, emissions reduced and the quality of products increased. We help you with analysis and control of the various processes, such as raw material preparation, crushing and grinding. Lumatics supports you benefiting most from modern technologies such as automation, sensors and data analysis.

This addresses issues such as CO2 reduction, waste management and environmental protection. By implementing sustainable production methods and technologies, companies can not only reduce costs, but also make a contribution to environmental protection.