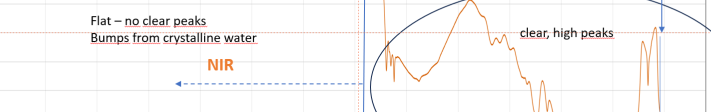

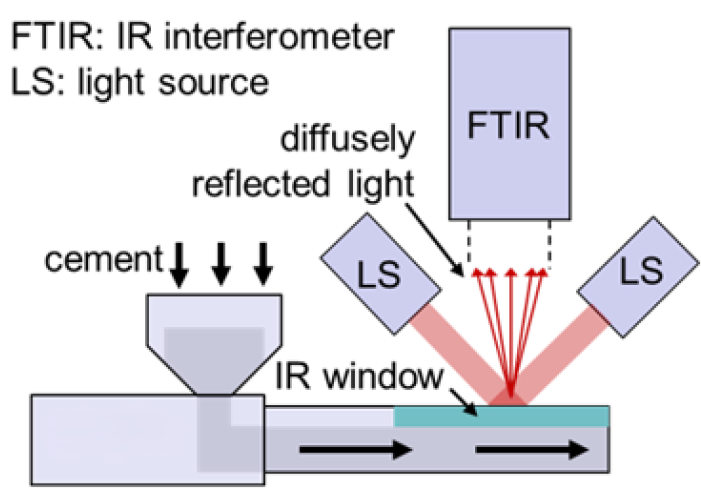

At-line Measurement Setup

- Low-cost plug and play measurement device, that delivers phase and oxide analysis comparable to XRF/XRD in real-time at several positions in the clinker and cement manufacturing processes

- Direct powder analysis without need for heavy pre-processing (no tablets)

- Easy handling and integration, no radioactive source

- Calibration with automatic site-specific adaptation

- Moderate CAPEX by low yearly maintenance costs

- Suitable for any powder

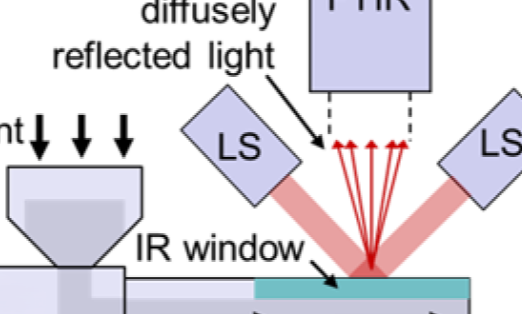

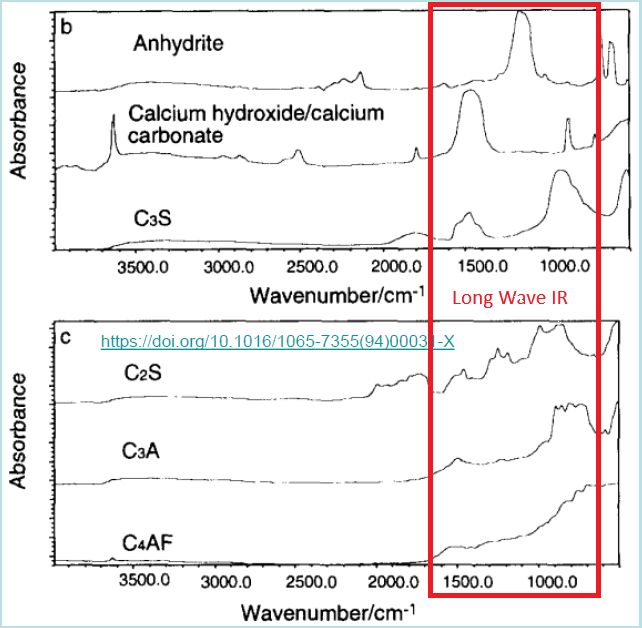

Long-Wave Infrared Cement Phase Applications

Distinct features allow quantification and qualification of cement mineral phases as well as sulphate hydration identification.LumaAPC delivers Model Predictive Controlled feeder setpoints for:

- Cement Phase detection and additives control

- Sulphate Identification and Control

- Strength prediction and Control

Values every minute allow for lag-free control and minimize statistical errors

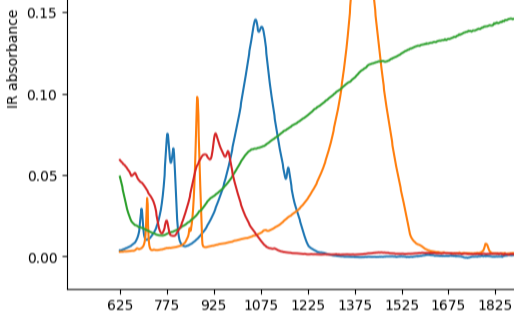

Long-Wave Infrared Raw Material Applications

Distinct features allow quantification and qualification of raw material oxides and phases. LumaAPC delivers Model Predictive Controlled feeder setpoints for:

- Lime Saturation Factor (LSF) Control

- Silicamodul (SM) Control

- Aluminamodul (AM) Control

Values every minute allow for lag-free control and minimize statistical errors

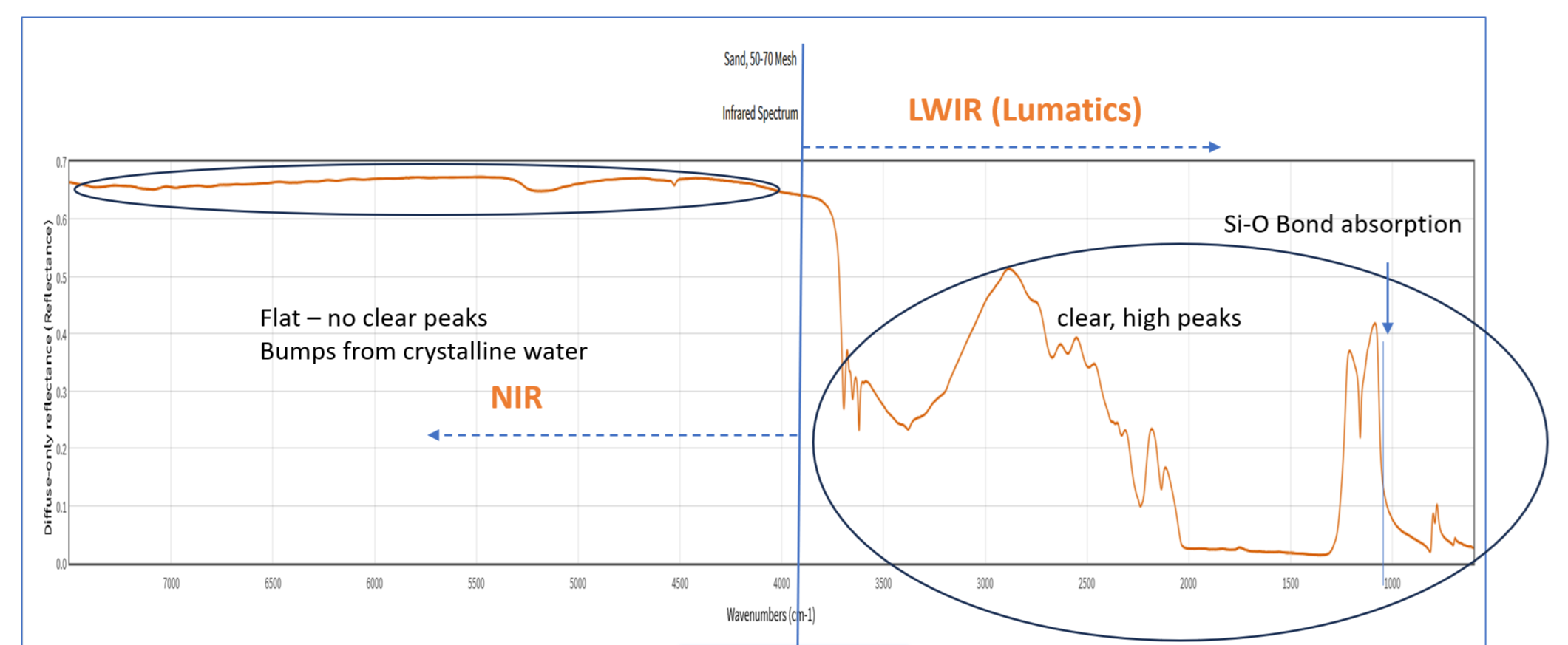

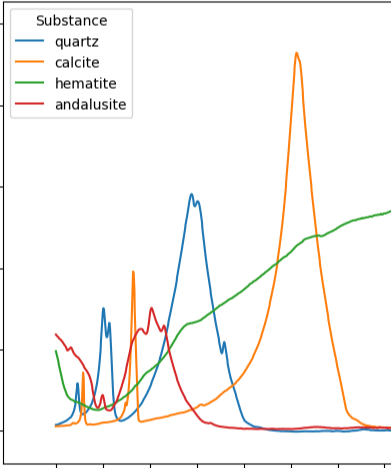

SiO2 - Excellent features in the LWIR - Superior performance

No overlapping features, good material characterization

Get the signal where it s created

Much clearer SiO2 signature compared with NIR