Fast analysis and data aquisition

- Low-cost plug and play measurement device, that delivers phase and oxide analysis comparable to XRF/XRD in real-time at several positions in the clinker and cement manufacturing processes

- Direct powder analysis without need for heavy pre-processing (no tablets)

- Easy handling and integration

- Calibration with automatic site-specific adaptation

- Moderate CAPEX by low yearly maintenance costs

Process control

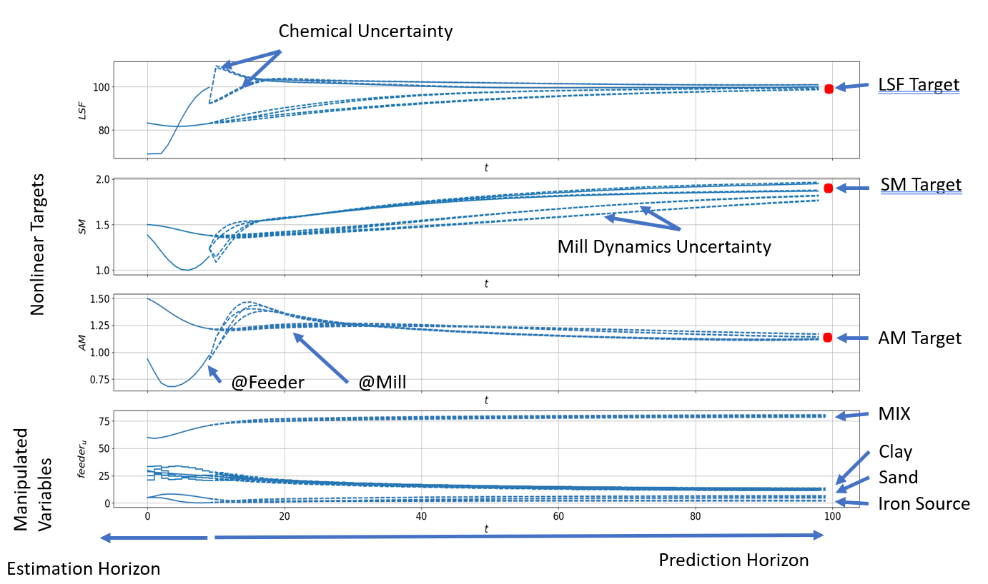

- Predictive control framework for robust trajectory and setpoint optimization

- Integration of AI based machine learning models

Measurement positions and applications

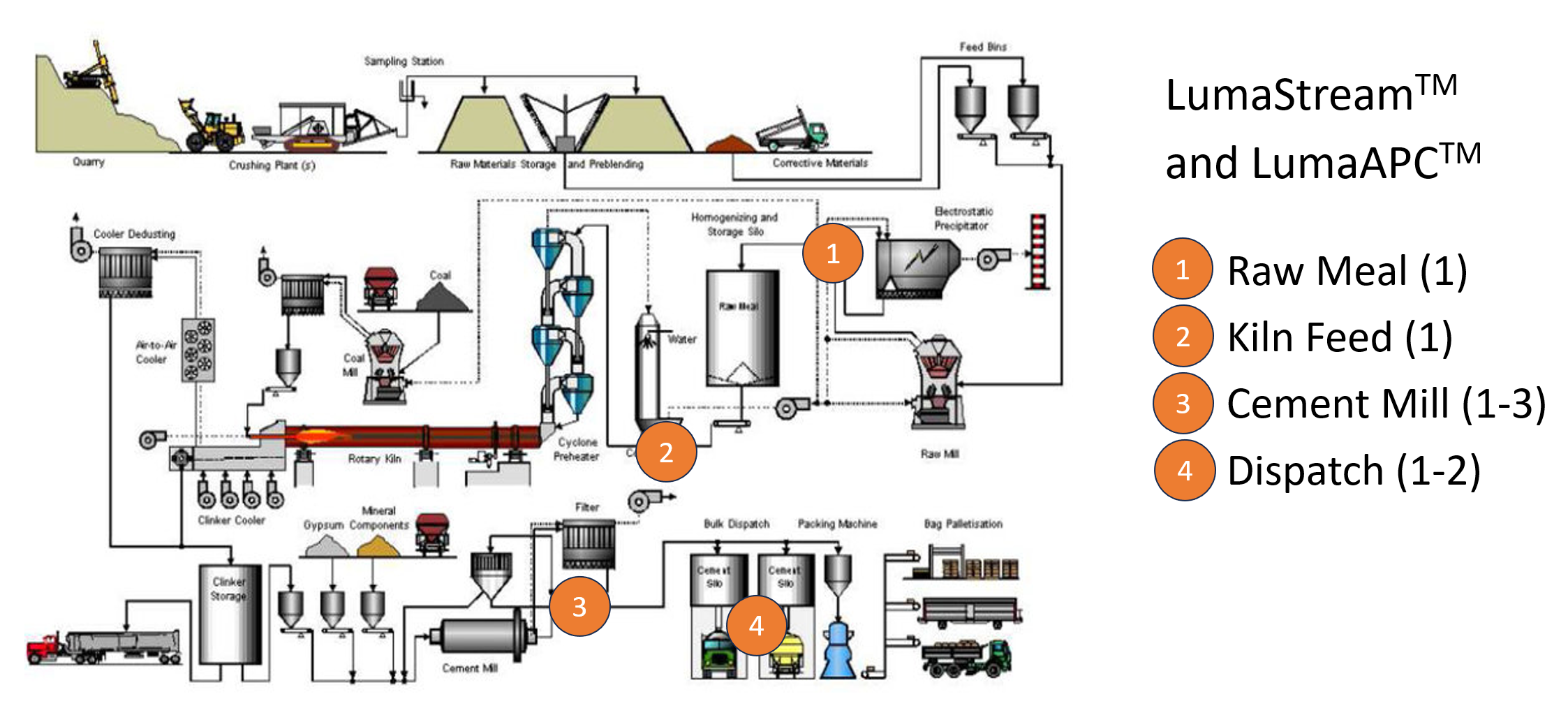

- Raw Mill: Raw mix proportioning

- Kiln Feed: Burning zone feed forward

- Cement Mill: strength prediction control, sulphate control, filler dosing

- Dispatch: Additive mixing, dispatch quality control

- Laboratory: Quality control, strength prediction, material characterization, receiving inspection

CO2 Reduction

- Improved cement phase building, through optimized raw material variability and stable burning zone

- AI based predictions and adaptive calibration

- Close target mixtures with minimal clinker factor

LumaStream

Real Time Process Measurement and Optimization

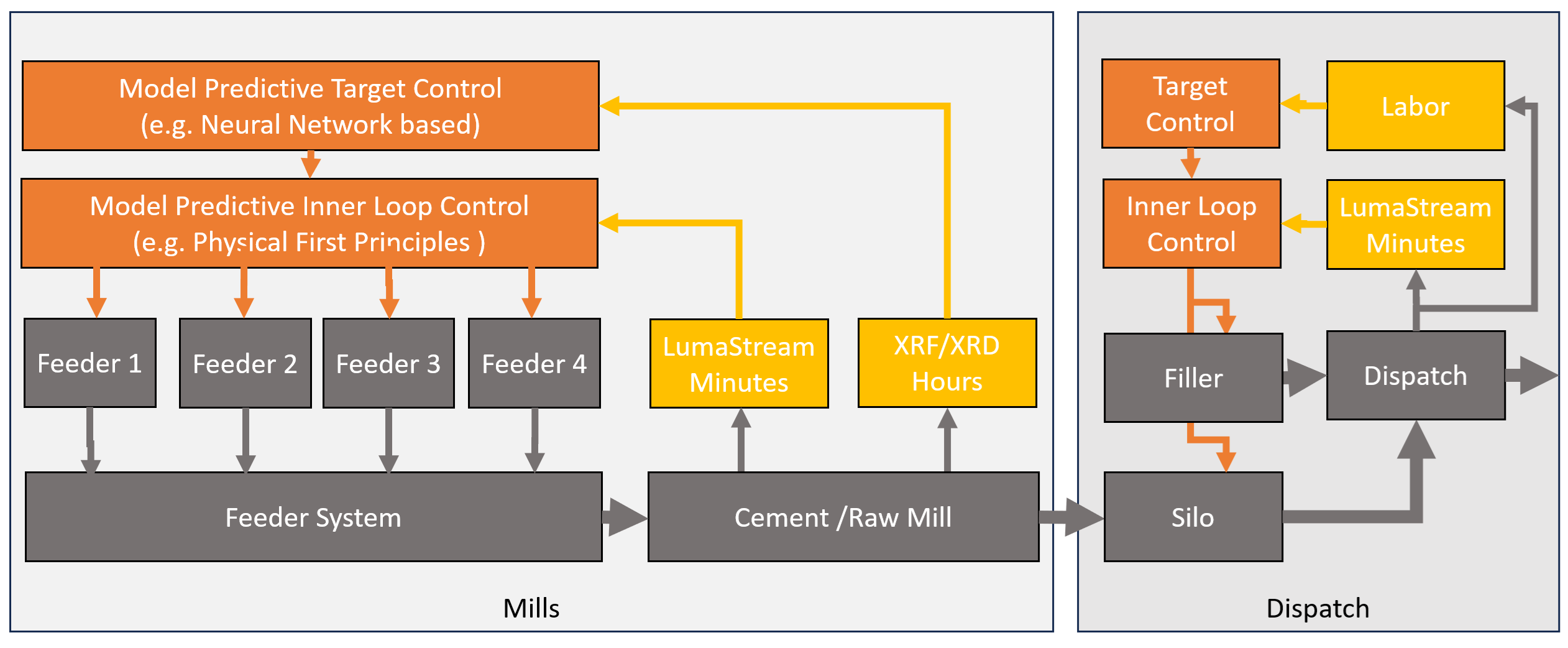

Analytics play a crucial role in the process control of cement production. By analyzing the composition and quality manufacturers can ensure the consistency and efficiency of their production processes. This data-driven approach allows for real-time adjustments to be made, optimizing the overall quality of the final product.

Our LumaStream at-line analyser delivers minute values for process control for elemental as well as phase analysis. This allows for real-time measurements comparable to XRF/XRD.

Our patented long-wave infrared technology delivers fast and reliable, hardzard free, results suitable for excellent on-target control.

LumaAPC

Advanced Process Control Solutions

By optimizing processes, resources can be saved, emissions reduced and the quality of products increased.

An important aspect is the monitoring and control of the various process steps, such as raw material preparation, crushing, and grinding. By using modern technologies such as automation, infrared sensors and data analysis, Lumatics helps to continuously monitor and optimize your cement production process.

LumaAPC's technology includes:

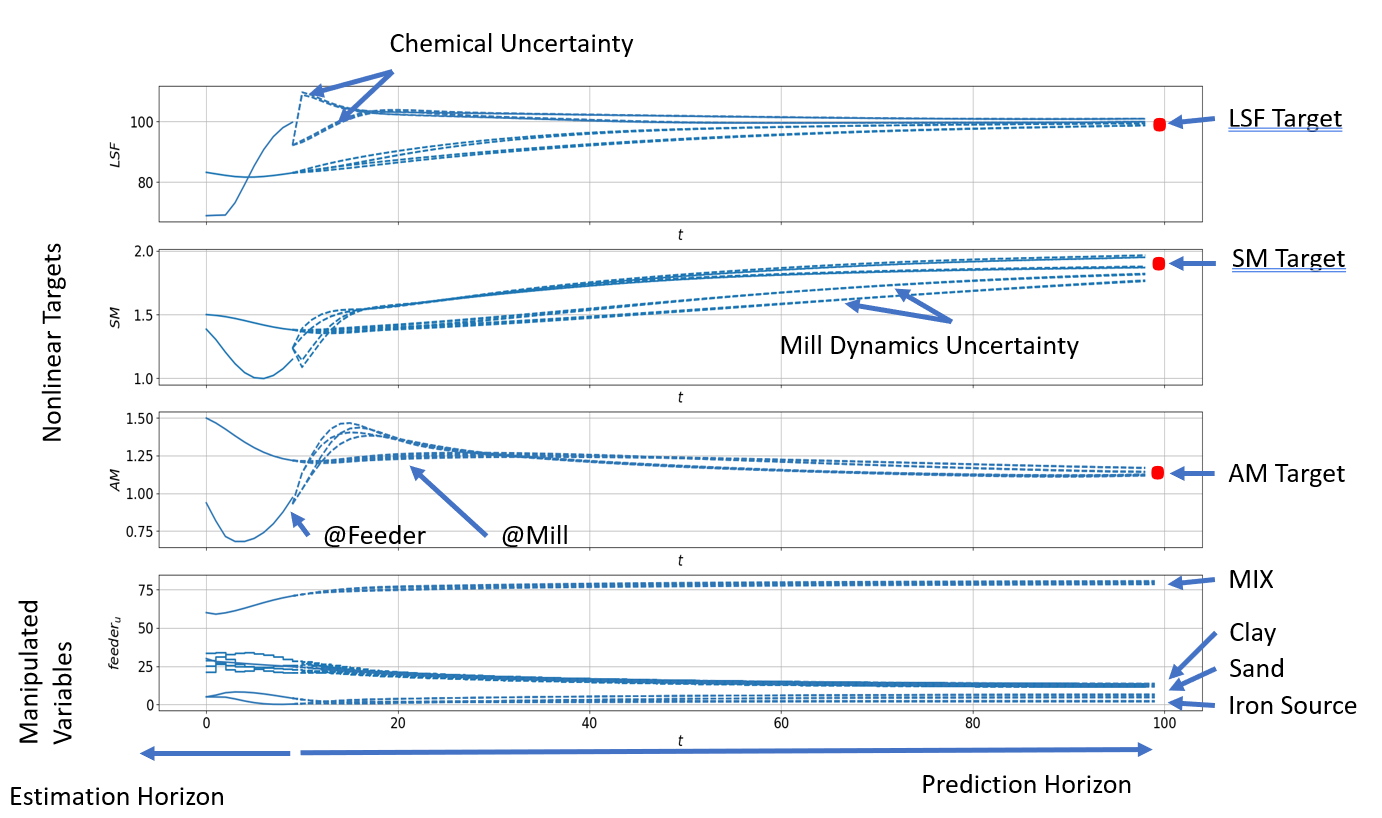

- Robust consideration of bounds and uncertainty

- Framework allows use of neural nets as prediction models

- State estimation through moving horizon

- Economic and environmental nonlinear optimization targets in addition to process targets possible

- Possiblity to include your strength prediction model

LumaLab

Advanced Laboratory Analytics

Our laboratory solution allows for material characterization, cement phase analysis, strenght prediction and is extremely easy to maintain. Just fill the bucket, let it run and get your result within minutes.

No extensive preparation required such as pressed tablets.

Direct comparison to XRF/XRD